Features of the M Series

This equipment performs surface modification by coating ceramic thin films.

By making full use of our unique "smooth coating technology" for coating,excellent film quality and high productivity have been realized.

This is an arc ion plating machine that has gained a lot of trust and achievements due to this feature.

Short process time

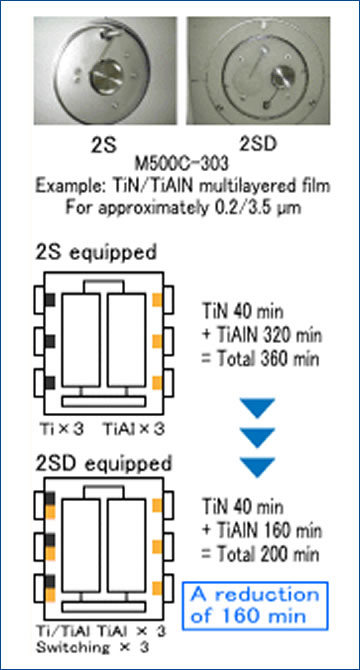

The arc evaporation method with high plasma density realizes high-speed processing and high adhesion. With a compactly designed 2SD evaporation source for multi layered films, short-cycle and low cost have been realized.

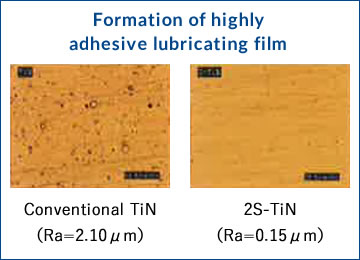

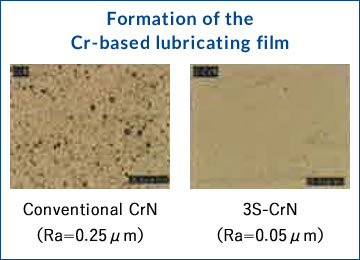

Smooth coating technology

Succeeded in reducing droplets while maintaining productivity, The smoothness, adhesion, and wear resistance of the coating have been dramatically improved.

Multi layered films

By adopting a 2SD evaporation source that can switch between two targets,

It is possible to form a variety of composite and laminated films in a short time.

This feature facilitates coating film development for users.

Low running cost

By combining optimal equipment configuration and process program, Coating with excellent film thickness uniformity is possible in a short time.

Low running costs have been achieved by increasing the efficiency of material use.

Operability and maintainability

With a single button, the film deposition process can be automatically processed from start to finish. Operation management can be easily performed by data management function and self-diagnosis function. Maintenance is easy due to the large two-sided door for easy access into the chamber.

Reliable, safe and flexible

We have achieved high reliability and safety based on our track record of more than 30 years.

High backward compatibility allows flexible support such as upgrading parts.

Selectable arc evaporation source variation

2S evaporation source

Focus on the source of evaporation

Total control

- Optimal magnetic field control

- Precise atmosphere control

- Cathode temperature control

- Established a film deposition process that maximizes the above performance

2SD evaporation source

High-speed deposition of

multi layered films by target switching

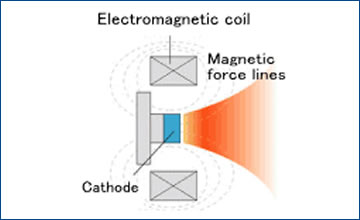

3S evaporation source

Achieves redissolution

in high magnetic field

A high magnetic field is generated by the electromagnetic coil, and the metal evaporated by the arc is redissolved to reduce the size of the macro particles.

M series lineup and standard specifications

| M500C | M500D | M720E | MF720 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Machine model | M500C-600 | M500C-060 | M500C-303 | M500D-800 | M500D-080 | M500D-404 | M720E-A00 | M720E-0A0 | M720E-505 | MF720 | ||

| Recommended coating zone | φ500×H400[mm] | φ500×H600[mm] | φ720×H800[mm] | φ720×H800[mm] | ||||||||

| Number of evaporation sources | 6units | 8units | 10units | 5units | ||||||||

| Evaporation source unit configuration | 2S×6 | 3S×6 | 2S×3 2SD×3 |

2S×8 | 3S×8 | 2S×4 2SD×4 |

2S×10 | 3S×10 | 2S×5 2SD×5 |

MFA evaporation source x5 | ||

| Attached Fixture table | 8-axis rotary Fixture | 8-axis rotary Fixture | 12-axis rotary Fixture | 12-axis rotary Fixture | ||||||||

| Film formation method | Cathode arc ion plating | |||||||||||

| Base material etching method | Gas bombardment, Metal bombardment | |||||||||||

| Cathode size | φ64Xt32 | |||||||||||

| Number of doors | 2 doors | |||||||||||

| Gas system | 4 standard systems | |||||||||||

| heater | standard equipment | |||||||||||

| Temperature monitor | Standard equipment (2 thermocouple measurement points) | Standard equipment (3 thermocouple measurement points) | ||||||||||

| Main exhaust pump | Turbo molecular pump | |||||||||||

| Recommended installation space | W4500×D5300×H3000[mm] | W4500×D5300×H3000[mm] | W5000×D6500×H3000[mm] | W5000×D6500×H3000[mm] | ||||||||

Typical coating film properties.

| Film type | TiN | TiCN | TiAlN | CrN | AlCrN | DLC |

|---|---|---|---|---|---|---|

| TiN Titanium nitride | TiCN Titanium carbon nitride | TiAlN Titanium aluminum nitride | CrN Chromium nitride | AlCrN Aluminum chromium nitride | DLC diamond-like carbon | |

|

|

|

|

|

|

|

| Color | Gold | Gray~Purple | Purple | Silver | Black Gray | Black |

| film thickness(μm) | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 | 0.1~20 |

| Vickers hardness(Hv25gf) | 1800~2200 | 2000~3000 | 2000~3000 | 1200~2200 | 2000~2500 | 15~70 (GPa) |

| Wear resistance | 〇 | ◎High load sliding environment | ◎High temperature cutting environment | ◎High load sliding environment | ◎High temperature cutting environment | ◎Sliding environment |

| Heat resistance(℃) | 600 | 500 | 800 | 800 | 900 | 450 |

| Processing temperature(℃) | 400~480 | 400~480 | 400~480 | 400~480 | 400~480 | 150~300 |

| Application example | General cutting tools General-purpose molds |

Punch/Die Sliding parts |

High-speed cutting tools High-temperature molds |

Machine parts/Engine parts Cr plating alternative |

High-speed cutting tools high-temperature molds |

Machine parts / Engine parts cutting tools |

| Film characteristics | general purpose Film | Low coefficient of friction high hardness |

High temperature oxidation resistance | Abrasion resistance heat resistance |

High temperature oxidation resistance | Low coefficient of friction high hardness |

* In addition, the ITF coating machine can coat variety of films depending on the type and Layout of Evaporation source.