FINE COATING MACHINE

Fine coating machine sale

Next generation arc ion plating system,

makes possible unprecedented low-cost,

short-cycle coating processing (compared to our conventional products).

FINE COATING MACHINE

Fine coating machine sale

Next generation arc ion plating system,

makes possible unprecedented low-cost,

short-cycle coating processing (compared to our conventional products).

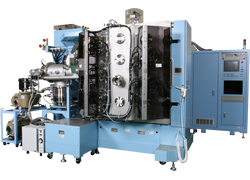

ITF's PVD Machine mainly adopts the arc ion plating method and the sputtering method. The arc ion plating method is characterized by high adhesion and smooth film due to its unique evaporation source. The sputtering method can form an ultra-smooth film with few pinholes and can be used for various purposes.

What is PVD?Since 1985, we have been developing Coating machine using arc discharge. ITF coating machine is based on high-voltage technology and vacuum technology, and the technology created by many years of research and development is applied. It is a coating machine with high performance such as film smoothness and excellent cost performance.

smoothness of film

ITF coating machine can keep productivity and coat high quality film.It reduces droplets that occur and stick, as much as possible and coat a highly wear-resistant film.

We have prepared sample coating pieces for various films.Please contact us

Lineup of coating machine model

and Arc evaporator

We will make the best proposal from various coating machine models and arc evaporator.

We will propose the most suitable coating machine for the film type, production scale, and budget of the customer.

Reasonable price

Each and every one of our machine is manufactured at our factory in Kyoto, Japan, under the ISO 9001 system of strict quality standards.

Most of the major parts are made in Japan and assembled in our factory, and basically sell to customer directly with more reasonable prices than other companies.

Nippon ITF Co., Ltd. has a track record of selling PVD coating machines that meet customer needs.

We are expanding not only in Japan but also in Asia and North America, so even if you are considering purchasing overseas, we can sell equipment and provide after-sales service. Due to the high level of satisfaction with our PVD machines and after-sales service, they chose us when installing the second and third machines.

This is a basic model of the ITF coating machine lineup, it has a round flange for mounting the arc evaporator, works well in low temperature coatings of metal nitride films.

This is a basic model of the ITF coating machine lineup, it has a round flange for mounting the arc evaporator, works well in low temperature coatings of metal nitride films.

Furthermore it is used as a platform for DLC coating machine.

catalog download

This is a new model of ITF coating machine lineup, it has a rectangle flange for mounting the arc evaporator, can install many arc evaporators and a sputter evaporator.

This is a new model of ITF coating machine lineup, it has a rectangle flange for mounting the arc evaporator, can install many arc evaporators and a sputter evaporator.

This is the core model of metal nitride coating machine.

catalog download

| Type | film | M500C | M500D | M720E | MF720 | iDS-mini | iDS-500 | iDS-720 | iDS-1000 |

|---|---|---|---|---|---|---|---|---|---|

| Arc | Metal nitride film(*) | 〇 | 〇 | 〇 | × | 〇 | 〇 | 〇 | 〇 |

| DLC(**) | 〇 | 〇 | 〇 | 〇 | 〇 | × | × | 〇 | |

| Sputter | Metal nitride film(*) | × | × | 〇 | × | 〇 | 〇 | × | 〇 |

| DLC(**) | × | × | 〇 | × | 〇 | 〇 | × | 〇 |

(*)Titanium, chromium, and aluminum nitrides such as TiN, TiCN, TiAlN, and AlCrN are widely used.

(**)The arc method produces hydrogen-free DLC (ta-C).The sputtering method produces metal DLC (Me-DLC).

Please note DLC coating machine sale is limited only to in-house production customer.

2021-11

2021-06

2021-06

2020-12

2020-04

We offer various services such as Inspection diagnosis ,parts exchange , on-sight service, overhaul to make customer purchased system to be stable, operatable, keeping performance.

If a problem occurs, we will contact you by phone or e-mail to confirm the details of the problem and resolve it. We will offer web meeting or remote access support by customer's request.

If it is difficult to recover with remote support, our support staff will visit your factory and take recovery measures.

* Lead time that our stuff visit will be discussed./p>

In the event of failure of your vacuum equipment, process power supply/control equipment, etc., we will lend you a replacement machine and provide quick recovery.

We offer to help, coating technical inquiry, consult system modification to meet customer's request, technical consulting, training of machine operation and/ or maintenance.

Our engineers will visit your factory to inspect and clean up arc evaporator, vacuum exhaust valves, drive units, and replace consumables such as vacuum seals.

We accept send-back overhauls for vacuum pumps and power supplies. If you wish, our service engineer can perform replacement work and operation check.

We are preparing many options according to customer's request.

For example, we manufacture fixtures that match the customer's base material, modify equipment, etc.

Please feel free to contact us when you purchase the equipment, even after the purchase.

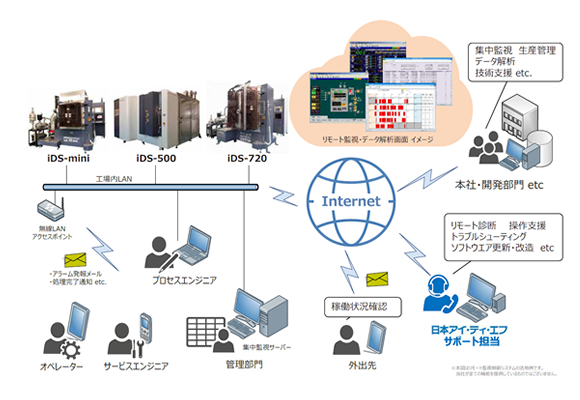

You will be notified by e-mail when an alarm occurs on your equipment.

You can monitor and operate the coating machine from a remote location via the network.

Our engineers will remotely diagnose your system and solve the problem.