Typical coating film properties.

The formation of hard films using arc discharge is mainly metal nitrides.

These are conductive materials and by applying a negative voltage to the substrate,A hard film can be formed by the action of ions from the plasma.

Depending on what metal is selected for vapor deposition, the characteristics of the film change and the optimal application is different.

Generally, it exhibits wear resistance with a film thickness of about 3 microns.

| Film type | TiN | TiCN | TiAlN | CrN | AlCrN | DLC |

|---|---|---|---|---|---|---|

| TiN Titanium nitride | TiCN Titanium carbon nitride | TiAlN Titanium aluminum nitride | CrN Chromium nitride | AlCrN Aluminum chromium nitride | DLC diamond-like carbon | |

|

|

|

|

|

|

|

| Color | Gold | Gray~Purple | Purple | Silver | Black Gray | Black |

| film thickness(μm) | 2~4 | 2~4 | 2~4 | 2~4 | 2~4 | 0.1~20 |

| Vickers hardness(Hv25gf) | 1800~2200 | 2000~3000 | 2000~3000 | 1200~2200 | 2000~2500 | 15~70 (GPa) |

| Wear resistance | 〇 | ◎High load sliding environment | ◎High temperature cutting environment | ◎High load sliding environment | ◎High temperature cutting environment | ◎Sliding environment |

| Heat resistance(℃) | 600 | 500 | 800 | 800 | 900 | 450 |

| Processing temperature(℃) | 400~480 | 400~480 | 400~480 | 400~480 | 400~480 | 150~300 |

| Application example | General cutting tools General-purpose molds |

Punch/Die Sliding parts |

High-speed cutting tools High-temperature molds |

Machine parts/Engine parts Cr plating alternative |

High-speed cutting tools high-temperature molds |

Machine parts / Engine parts cutting tools |

| Film characteristics | general purpose Film | Low coefficient of friction high hardness |

High temperature oxidation resistance | Abrasion resistance heat resistance |

High temperature oxidation resistance | Low coefficient of friction high hardness |

* In addition, the ITF coating machine can coat variety of films depending on the type and Layout of Evaporation source.

Coating Examples

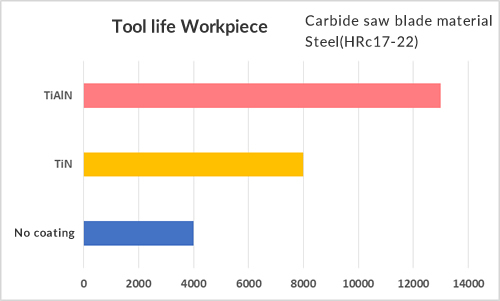

carbide saw blade [Tin,TiAlN]

| Coating type | TiN,TiAlN |

| Tool Name | carbide saw blade |

| Workpiece material | steel(HRc17-22) |

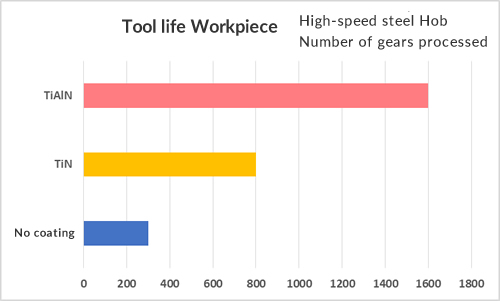

high-speed steel Hob tool φ100xL180 [Tin,TiAlN]

| Coating type | TiN,TiAlN |

| Tool Name | high-speed steel Hob tool φ100xL180 |

| use | Mission gear processing |

| Processing conditions | Water-soluble coolant |

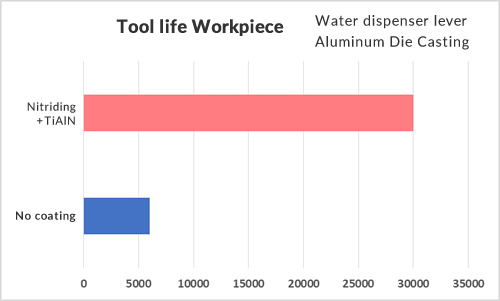

Die casting [TiAlN]

| Coating type | TiAlN |

| Tool Name | Die Casting Pin |

| Product Name | water dispenser lever |

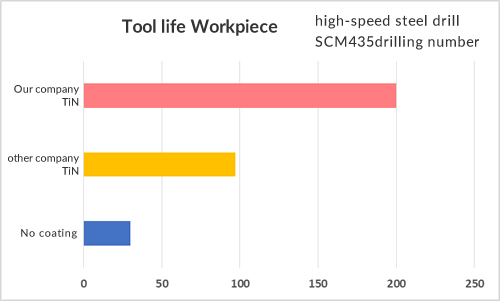

high-speed steel drill [Tin]

| Coating type | Tin |

| Tool Name | high-speed steel drill |

| Workpiece material | SCM435 t=20mm |

| Material processing conditions | Speed-18.8m/min Travel-0.1mm/rev |

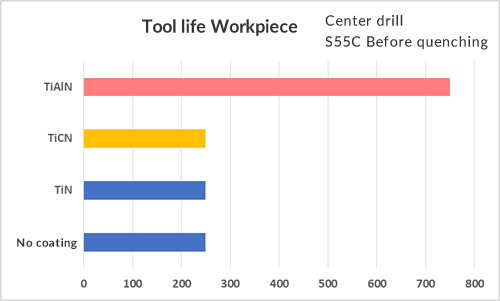

Center drill [Tin,TiCN,AlTiN]

| Coating type | Tin,TiCN,AlTiN |

| Tool Name | Center drill |

| Workpiece material | S55C Before quenching |